Fluidized Bed Coolers / Dryers

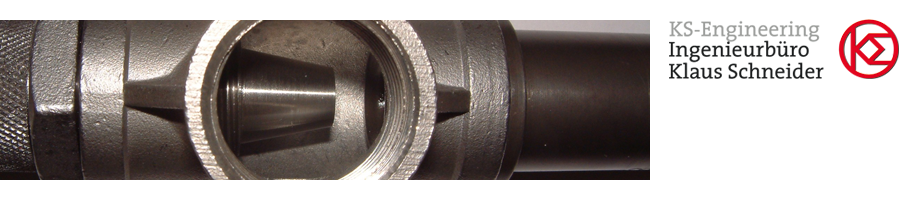

The most important qualities of Fluidized Bed Coolers / Dryers are their high heat transfer coefficient (>180W/m²K) and the equal cooling / drying result. Our fluidized bed coolers are working continuously and are fed by example by rotary valves or screw conveyers. The installation height is smaller than this of comparable stiff coolers. By patended air nozzles the complete content of the cooler is fluidized very equally. It is also possible to add other materials without problems. With the help of a patended separator oversize particles are separated with a high efficiency and security already before entering the dryer. On page three (3) the total view of a fluidized bed cooler is shown.

Field of Operation:

- Cooling of sand in casting industry

- Cooling of solids in chemical industry

- Drying of solids in chemical industry

- Fluid bed reactor in environmental industry

Dimensions:

Deliverable types and dimensions are shown in view 2, enclosed table demonstrates the performance of this coolers for the cooling of used sand in casting plants.