Wear indicators for silo delivery devices

To protect against wear in pneumatic conveying lines special wear inserts can be used, eg. cast basalt wear pads or hardened liners and inserts. These bends are also commercially available with a wear indicator. In particular in the conveying of contaminated materials (eg. used active coke) it is beneficial for safety reasons. At the same time the entire conveying line (eg. through double walled pipe) is monitored.

The entry of the conveying air mixture is frequently done through a 90° bend with a very small R/D ratio, therefore the line can become reduced at the silo. eg, the use of a long bend on the top of the silo can be avoided, therefore saving head space. This delivery system has the further possibility to decellerate the material delivery so that it is smoothly poured into the silo, and a cross-sectional divergence slows the delivery by up to 5 times. Therefore further controlling the delivery in a single operation.

These silo delivery systems are available in the following forms:

- as a casting (eg. chilled cast iron)

- with a cast basalt lining

- a bend with bulge, material collects in the bulge and acts as a wear pad.

- fabricated design with impact plate (this type has interchangeable parts)

These systems were previously not equipped with wear indicators even though they were subject to high wear situations. The point that is exposed to wear is mainly the section of the bend where the centreline of travel meets the outside radius. A worn out system often has no indication untill it is too late, then it requires a costly operation to be ammended or in most cases completely rebuilt (not to mention the time that the system is shut down during maintainence).

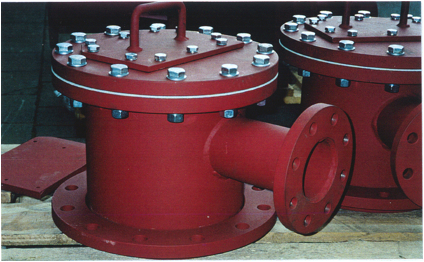

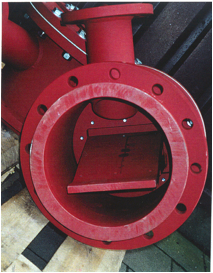

KS-Engineering designed an inovative silo delivery device for a north German municipal waste incineration plant, the component was also equipped with a wear indicator. (fig 1.) In the existing system a DN80 vertical pipe ran into a DN250 device, and was mounted on a DN250 flange mount. The delivery manifold was equipped with a wear plate made from hardened steel (min.53 HRV), which is bolted into the top of the dome facing down at 20 degrees off vertical. The plate fills almost the entire width of the manifold, (dia.2). The material meets in the dome then runs over the wear plate. Through the employment of the 20° angle the sprayed material is directed down. Due to the physical size of the wear plate, (180mm wide x 220mm long) and the perpendicular exit, only a minimal amount of sprayed material comes into contact with the steel housing or the mounting . Through the impact on the wear plate and the dimentioning of the delivery device the mass flow falls calmly into the silo. There is an initial delay of the mass flow at the entrance to the device and then the pipework is increased in size at the silo entry. The conveying pipe is connected via a flanged connection. There is a gasket between the flange to seal the unit.

The wear plate is joined to the underside of a plate with a U-profile handle welded on the top of the plate, the plate is then bolted to the lid of the delivery dome. This allows easy access to inspect the state of the wear plate and the lid as well as the internals of the delivery dome, and simple exchange of the wear plate if required.

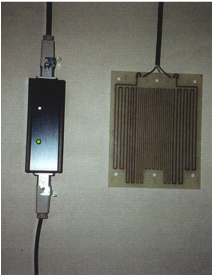

As a further improvement to the system, a wear indicator can be mounted between the 20°angle diverter plate and the replaceable wear plate (see diagram3). This consists of a printed circuit board.The circuit board has a metallic circuit printed onto it, this covers the entire board. The circuit board is bolted in place between the existing angled plate and a replaceable wear plate. Both ends of the printed circuit board are connected to a monitoring panel. This is then mounted on the outside of the silo entry dome. The cable runs behind the angled plate so that it is protected from the flowing material. With a 24 volt D.C. powered monitoring panel and a simple LED panel consisting of a red and green light, these register a reading of the wear plates condition. When the plate is not worn the signal simply runs through the circuit and back to the LED panel, in this condition the green light is displayed. When the wear protection plate is finally penetrated the flowing material then breaks down the circuit board, therefore breaking the circuit. In this situation the red light is then activated. The signal can be sent through another port and cable to a monitoring panel in the control room, from there the condition of the wear protection plate can be monitored. The panel has both visual and accustic warning signals. At the same time that the circuit on the circuit board is worn through a signal is registered. The exchange of the wear protection plate and the indicators can be quickly carried out by one person so that extended down time and further damage can be avoided.

This installation system of a silo delivery dome with internal exchangeable wear protection plate and wear indicator is a good value for money compared to others currently available on the market. In the worn condition only the wear protection plate and the indicator need to be replaced, not the entire unit. The monitoring system is also more reliable and with readily available spare parts a quicker reaction to maintainenance is possible.

Dia 1: Silo delivery dome DN80, complete with flanged lid

Dia 2:inside view of the unit, showing the wear plate

Dia 3: indicator panel and circuit board